Products

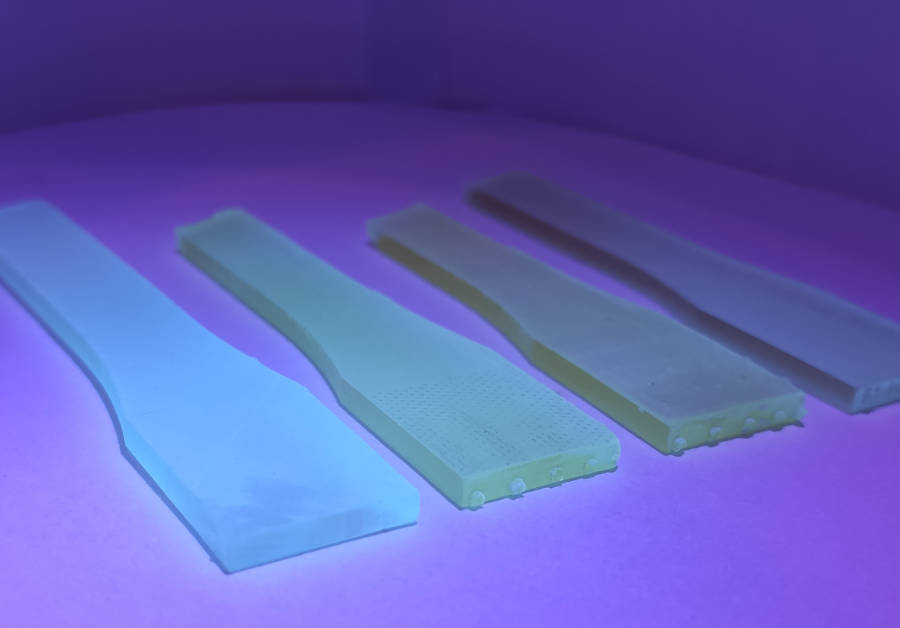

TOUGH resin

High stiffness and high mechanical strength modules. It comes in natural, sand, blue, black, grey and red colours. This resin is dedicated for intermediate users and requires moderate postcuring conditions.

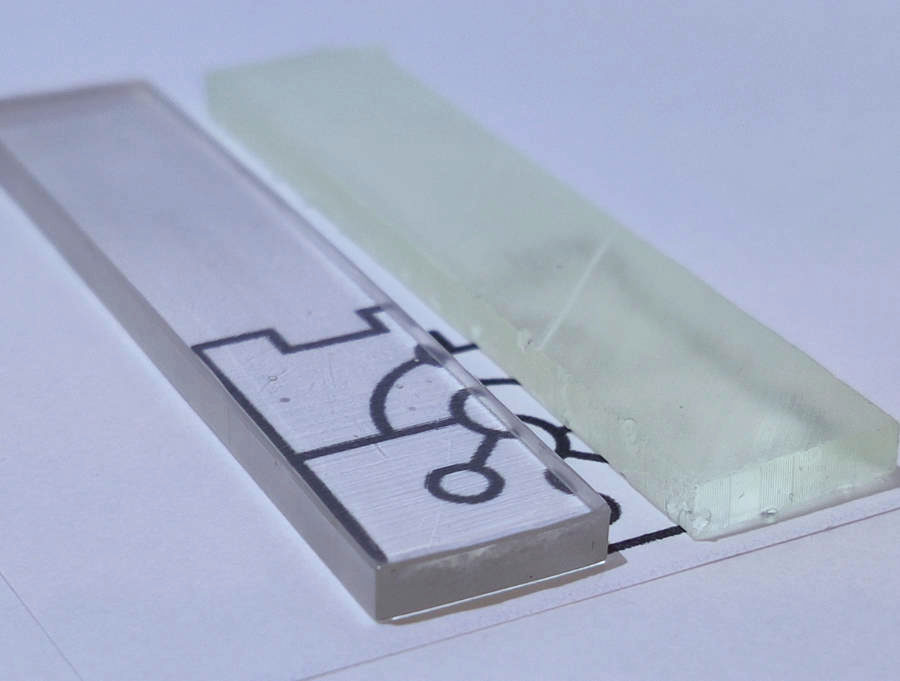

DENTAL resin

Formulated to minimize polymerization shrinkage while maintaining high mechanical resistance. Due to the specially selected group of raw materials, this resin proves itself when high precision printing combined with strength and environmental resistance is required. DENTAL resin is available in gum-like pink colour under the name GUM, and in bone tissue colour and structure under the name BONE.

CLEAR resin

Has been developed for use in areas requiring high transparency. Printouts obtained from this resin are transparent, and after polishing process, can be used as a lens material. This resin has moderate mechanical parameters.

ABSlike resin

Models printed from this resin combine high impact strength with the characteristics of a rigid material. They do not break when deformed, so they are ideal for the production of prototypes of moving parts of devices. The resin is available in black and grey colour.

All-in-one photopolymerization of eco-friendly hybrid resins in 3D low-cost technologies

Some said that technology causes more problems than it solves. Therefore, our technology is addressed to resolve the issues of 3D resin printing using novel solutions based on new functional photoinitiators. Our photoinitiators are a group of compounds that can be adopted in any 3D printing industry and fill a gap in the market that needs good and proven solutions. The scientific part of the project is based on the staff’s extensive experience in researching the kinetics of the photopolymerization process and developing new innovative cationic and radical photoinitiators. Thanks to the knowledge of raw material bases and experience in developing parameters of photosensitive resins for their applications, the company can offer its services in various industries using photopolymerization processes in the service of 3D printing.

The technology is based on applied photochemistry fundamentals, including Vis-LED visible light, providing a broad spectrum of possibilities. The main problem faced by 3D printing using light-cured materials is the narrow base of raw materials, especially among resins with high mechanical parameters. There are no resins on the market that combine features such as mechanical and abrasion resistance or anti-staticity, and applications for such solutions are extensive, ranging from dental materials to resins for prototyping machine parts. The key to this problem is custom-made products, whose parameters are precisely matched to market demand. Thanks to Photo4Chem, our partners reduce their R&D department costs, making them eager to develop and produce the material they care about.

The proposed technology is a practical commitment of its inventors. After great scientific effort and designing 3D printing technology of resins and highly selected photoinitiators for this process. The correctness of the operation of the offered technologies was tested in industrial conditions, and the obtained materials were examined for mechanical strength, impact strength, abrasion resistance, and specific resistance. In the case of each of the developed photosensitive compositions, the parameters of the developed material met the requirements of the customers and provided a significant improvement in comparison to market raw materials.

Even with the best technology, there will always be gaps that show up after years of use. In contrast, the developed technology has protected safeguards that can react quickly and improve 3D print properties.

A research team composed of specialists with broad experience in various fields of photochemistry and polymer chemistry, thanks to the exchange of knowledge and experience, enables a thorough understanding of photopolymerization processes, the operation of initiating systems, and the dependence of the parameters of the material obtained on its chemical composition.